Introduction to Catalysis and Industrial Catalytic Processes » książka

Introduction to Catalysis and Industrial Catalytic Processes

ISBN-13: 9781118454602 / Angielski / Twarda / 2016 / 352 str.

Introduction to Catalysis and Industrial Catalytic Processes

ISBN-13: 9781118454602 / Angielski / Twarda / 2016 / 352 str.

(netto: 517,04 VAT: 5%)

Najniższa cena z 30 dni: 539,55

ok. 30 dni roboczych.

Darmowa dostawa!

Introduces major catalytic processes including products from the petroleum, chemical, environmental and alternative energy industries

- Provides an easy to read description of the fundamentals of catalysis and some of the major catalytic industrial processes used today

- Offers a rationale for process designs based on kinetics and thermodynamics

- Alternative energy topics include the hydrogen economy, fuels cells, bio catalytic (enzymes) production of ethanol fuel from corn and biodiesel from vegetable oils

- Problem sets of included with answers available to faculty who use the book

Review:

-In less than 300 pages, it serves as an excellent introduction to these subjects whether for advanced students or those seeking to learn more about these subjects on their own time...Particularly useful are the succinct summaries throughout the book...excellent detail in the table of contents, a detailed index, key references at the end of each chapter, and challenging classroom questions...- (GlobalCatalysis.com, May 2016)

"In less than 300 pages it serves as an excellent introduction to these subjects whether for advanced students or those seeking to learn more about these subjects on their own time...Particularly useful are the succinct summaries throughout the book...excellent detail in the table of contents, a detailed index, key references at the end of each chapter, and challenging classroom questions..." (GlobalCatalysis.com, May 2016)

PREFACE XV

ACKNOWLEDGMENTS XVII

LIST OF FIGURES XIX

NOMENCLATURE XXVII

CHAPTER 1 CATALYST FUNDAMENTALS OF INDUSTRIAL CATALYSIS 1

1.1 Introduction 1

1.2 Catalyzed versus Noncatalyzed Reactions 1

1.3 Physical Structure of a Heterogeneous Catalyst 6

1.4 Adsorption and Kinetically Controlled Models for Heterogeneous Catalysis 10

1.5 Supported Catalysts: Dispersed Model 19

1.6 Selectivity 24

Questions 27

Bibliography 29

CHAPTER 2 THE PREPARATION OF CATALYTIC MATERIALS 31

2.1 Introduction 31

2.2 Carrier Materials 32

2.3 Incorporating the Active Material into the Carrier 37

2.4 Forming the Final Shape of the Catalyst 40

2.5 Catalyst Physical Structure and Its Relationship to Performance 45

2.6 Nomenclature for Dispersed Catalysts 45

Questions 46

Bibliography 46

CHAPTER 3 CATALYST CHARACTERIZATION 48

3.1 Introduction 48

3.2 Physical Properties of Catalysts 49

3.3 Chemical and Physical Morphology Structures of Catalytic Materials 54

3.4 Spectroscopy 65

Questions 66

Bibliography 67

CHAPTER 4 REACTION RATE IN CATALYTIC REACTORS 69

4.1 Introduction 69

4.2 Space Velocity, Space Time, and Residence Time 69

4.3 Definition of Reaction Rate 71

4.4 Rate of Surface Kinetics 72

4.5 Rate of Bulk Mass Transfer 78

4.6 Rate of Pore Diffusion 80

4.7 Apparent Activation Energy and the Rate–Limiting Process 82

4.8 Reactor Bed Pressure Drop 83

4.9 Summary 84

Questions 84

Bibliography 87

CHAPTER 5 CATALYST DEACTIVATION 88

5.1 Introduction 88

5.2 Thermally Induced Deactivation 88

5.3 Poisoning 96

5.4 Coke Formation and Catalyst Regeneration 99

Questions 101

Bibliography 103

CHAPTER 6 GENERATING HYDROGEN AND SYNTHESIS GAS BY CATALYTIC HYDROCARBON STEAM REFORMING 104

6.1 Introduction 104

6.2 Large–Scale Industrial Process for Hydrogen Generation 105

6.3 Hydrogen Generation for Fuel Cells 121

6.4 Summary 126

Questions 127

Bibliography 128

CHAPTER 7 AMMONIA, METHANOL, FISCHER TROPSCH PRODUCTION 129

7.1 Ammonia Synthesis 129

7.2 Methanol Synthesis 134

7.3 Fischer Tropsch Synthesis 140

Questions 144

Bibliography 145

CHAPTER 8 SELECTIVE OXIDATIONS 146

8.1 Nitric Acid 146

8.2 Hydrogen Cyanide 151

8.3 The Claus Process: Oxidation of H2S 154

8.4 Sulfuric Acid 155

8.5 Ethylene Oxide 159

8.6 Formaldehyde 160

8.7 Acrylic Acid 164

8.8 Maleic Anhydride 166

8.9 Acrylonitrile 166

Questions 168

Bibliography 169

CHAPTER 9 HYDROGENATION, DEHYDROGENATION, AND ALKYLATION 171

9.1 Introduction 171

9.2 Hydrogenation 171

9.3 Hydrogenation Reactions and Catalysts 177

9.4 Dehydrogenation 185

9.5 Alkylation 187

Questions 188

Bibliography 189

CHAPTER 10 PETROLEUM PROCESSING 190

10.1 Crude Oil 190

10.2 Distillation 191

10.3 Hydrodemetalization and Hydrodesulfurization 193

10.4 Hydrocarbon Cracking 197

10.5 Naphtha Reforming 200

Questions 202

Bibliography 203

CHAPTER 11 HOMOGENEOUS CATALYSIS AND POLYMERIZATION CATALYSTS 205

11.1 Introduction to Homogeneous Catalysis 205

11.2 Hydroformylation: Aldehydes from Olefins 206

11.3 Carboxylation: Acetic Acid Production 208

11.4 Enzymatic Catalysis 209

11.5 Polyolefins 210

Questions 213

Bibliography 213

CHAPTER 12 CATALYTIC TREATMENT FROM STATIONARY SOURCES: HC, CO, NOX, AND O3 215

12.1 Introduction 215

12.2 Catalytic Incineration of Hydrocarbons and Carbon Monoxide 216

12.3 Food Processing 225

12.4 Nitrogen Oxide (NOx) Reduction from Stationary Sources 226

12.5 CO2 Reduction 230

Questions 231

Bibliography 233

CHAPTER 13 CATALYTIC ABATEMENT OF GASOLINE ENGINE EMISSIONS 235

13.1 Emissions and Regulations 235

13.2 Catalytic Reactions Occurring During Catalytic Abatement 238

13.3 First–Generation Converters: Oxidation Catalyst 239

13.4 The Failure of Nonprecious Metals: A Summary of Catalyst History 240

13.5 Supporting the Catalyst in the Exhaust 242

13.6 Preparing the Monolith Catalyst 246

13.7 Rate Control Regimes in Automotive Catalysts 247

13.8 Catalyzed Monolith Nomenclature 248

13.9 Precious Metal Recovery from Catalytic Converters 248

13.10 Monitoring Catalytic Activity in a Monolith 248

13.11 The Failure of the Traditional Beaded (Particulate) Catalysts for Automotive Applications 250

13.12 NOx, CO and HC Reduction: The Three–Way Catalyst 251

13.13 Simulated Aging Methods 255

13.14 Close–Coupled Catalyst 256

13.15 Final Comments 258

Questions 259

Bibliography 261

CHAPTER 14 DIESEL ENGINE EMISSION ABATEMENT 262

14.1 Introduction 262

14.2 Catalytic Technology for Reducing Emissions from Diesel Engines 265

Questions 272

Bibliography 273

CHAPTER 15 ALTERNATIVE ENERGY SOURCES USING CATALYSIS: BIOETHANOL BY FERMENTATION, BIODIESEL BY TRANSESTERIFICATION, AND H2–BASED FUEL CELLS 274

15.1 Introduction: Sources of Non–Fossil Fuel Energy 274

15.2 Sources of Non–Fossil Fuels 276

15.3 Fuel Cells 279

15.4 Types of Fuel Cells 283

15.5 The Ideal Hydrogen Economy 293

Questions 294

Bibliography 295

INDEX 297

Robert J. Farrauto, PHD, is Professor of Practice in the Earth and Environmental Engineering Department at Columbia University in the City of New York. He retired from BASF (formerly Engelhard) as a Research Vice President after 37 years of service. He has over 40 years industrial experience in catalysis and has commercialized a number of technologies in the environmental, chemical and alternative energy fields. He holds 58 US patents and over 115 peer–reviewed journal publications. He teaches graduate and undergraduate courses focusing on catalysis. He is a co–author of

Fundamentals of Industrial Catalytic Processes, 2nd Edition and

Catalytic Air Pollution Control: Commercial Technology, 3rd Edition.

Lucas Dorazio, PhD is a Research Chemical Engineer at BASF Corporation, Iselin, NJ where he is engaged in reforming and environmental technology. He is also Adjunct assistant professor at New Jersey Institute of Technology where he teaches environmental and industrial catalysis.

Calvin H. Bartholomew, PhD is Emeritus Professor at Brigham Young University. He continues to conduct catalysis research, is active in consulting and does specialized teaching for AICHE short courses in catalysis. He has been principal investigator or co–investigator on over 60 grants and contracts and has supervised more than 175 research students. He is the author or co–author of 5 books and 120 peer–reviewed papers and reviews with emphasis on catalysis.

Introduces a simplified description of major catalytic processes including products from the petroleum, chemical, environmental and alternative energy fields

Catalysis is central to the chemical industry, as it is directly or involved in the production of almost all useful chemical products. It is central to any technically advanced society from the manufacture of bulk and specialty chemicals, through the production of fuels by petroleum refining to the control of unwanted environmental degradation.

Introduction to Catalysis and Industrial Catalytic Processes explains the fundamental principles of catalysis and their applications of catalysis in a simple, introductory textbook that excites those contemplating an industrial career in chemical, petroleum, alternative–energy, and environmental fields in which catalytic processes play a dominant role. The book focuses on non–proprietary, basic chemistries and descriptions of important, currently–used catalysts and catalytic processes. Considerable practical examples, recommendations, and cautions located throughout the book are based on authors experience gleaned from teaching, research, commercial development, and consulting, including feedback from many students and associates.

The book features:

Basic principles of catalysis, including reaction kinetics, simple reactor design concepts, catalyst preparation, characterization, deactivation and regeneration

Applications and practice in the industry, including process chemistry, conditions, catalyst design, process design, and catalyst deactivation problems for each catalytic process and regeneration when appropriate

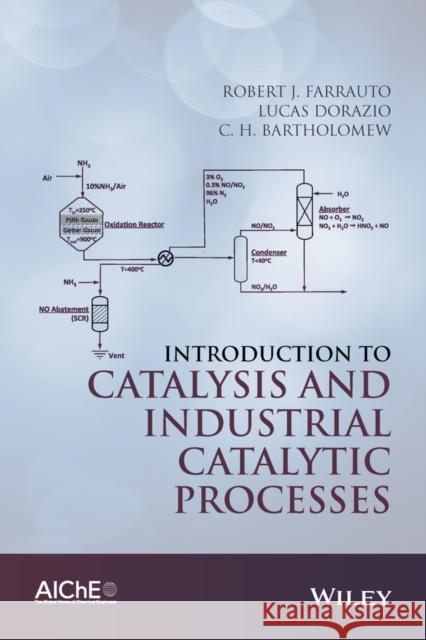

Simplified process diagrams providing an overview of principal process units (e.g. reactors and separation units) and important process steps, including reactant and product streams

Suggested readings (reviews, books, and journal articles) and Questions are included at the end of each chapter to encourage interested readers to deepen their knowledge of these topics

The need for a thorough understanding of fundamental principles of chemistry and catalysis is a given. Introduction to Catalysis and Industrial Catalytic Processes main objective is to transition this knowledge to their commercial applications, especially for the many chemistry and chemical engineering students who spend much of their careers working in industry with catalytic processes.

Robert J. Farrauto, PHD, is Professor of Practice in the Earth and Environmental Engineering Department at Columbia University in the City of New York. He retired from BASF (formerly Engelhard) as a Research Vice President after 37 years of service. He has over 40 years industrial experience in catalysis and has commercialized a number of technologies in the environmental, chemical and alternative energy fields. He holds 58 US patents and over 115 peer–reviewed journal publications. He teaches graduate and undergraduate courses focusing on catalysis. He is a co–author of Fundamentals of Industrial Catalytic Processes, 2nd Edition and Catalytic Air Pollution Control: Commercial Technology, 3rd Edition.

Lucas Dorazio, PhD is a Research Chemical Engineer at BASF Corporation, Iselin, NJ where he is engaged in reforming and environmental technology. He is also Adjunct assistant professor at New Jersey Institute of Technology where he teaches environmental and industrial catalysis.

Calvin H. Bartholomew, PhD is Emeritus Professor at Brigham Young University. He continues to conduct catalysis research, is active in consulting and does specialized teaching for AICHE short courses in catalysis. He has been principal investigator or co–investigator on over 60 grants and contracts and has supervised more than 175 research students. He is the author or co–author of 5 books and 120 peer–reviewed papers and reviews with emphasis on catalysis.

1997-2026 DolnySlask.com Agencja Internetowa

KrainaKsiazek.PL - Księgarnia Internetowa