Toward a CO2-neutral biotechnology: itaconate production using CO2 derived co-substrates » książka

Toward a CO2-neutral biotechnology: itaconate production using CO2 derived co-substrates

ISBN-13: 9783985551767 / Angielski / Miękka / 228 str.

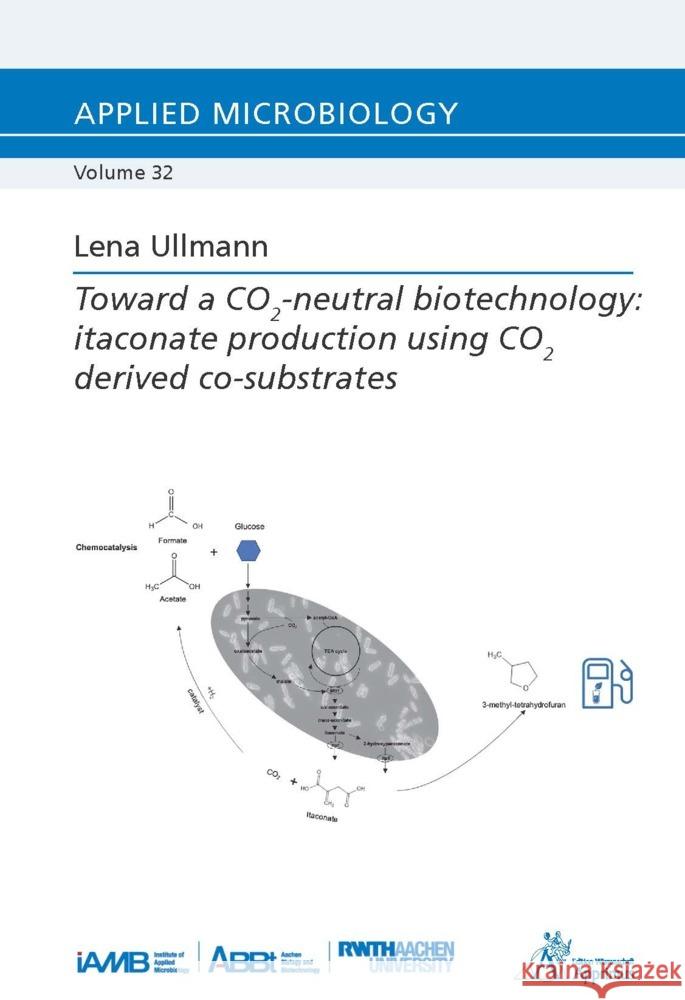

Climate change represents a severe global issue also driven by the consumption of fossil fuels, which ultimately release greenhouse gases into the atmosphere. Simultaneously, the rising demand for food, energy, and chemicals requires a shift from fossil to sustainable raw materials. Utilizing renewable carbon sources (i.e., biomass, CO2, organic waste) ensures a fossil-free future. Over recent years, itaconate has gained increasing interest as a prospective bio-based platform chemical. To replace nowadays petroleum-derived substances like methacrylic acid in industrial applications, enhancing the economic viability of the current biotechnological production processes using the fungus Aspergillus terreus is essential.Ustilaginaceae, a family of smut fungi, display a broad product spectrum featuring organic acids (e.g., itaconate, malate, succinate). These molecules are considered value-added chemicals with potential applications in the pharmaceutical, food, and chemical industry. Importantly, in combination with feeding alternative C-sources as (co-)substrates (e.g., acetate, formate, lignocellulose), these microorganisms offer excellent potential for reducing CO2 emissions and land use. This thesis focused on bioprocess optimization and metabolic engineering strategies to establish a sustainable, industrially relevant Ustilaginaceae itaconate production host competitive to A. terreus. Concerning the bioprocess optimization aspect, acetate and formate were inverstigated as co-substrates. Investigating the biodiversity using in total 72 Ustilaginaceae, Ustilago maydis MB215 and Ustilago cynodontis NBRC 9758 were identified as potential production hosts using these co-substrates in combination with glucose. Formate was supplied from chemical CO2 hydrogenation reactions using a biphasic Ru-catalyst without any purification, highlighting the many possibilities of combining chemo- and biocatalysis for carbon capture and utilization. Long-term itaconate production during the stationary phase was achieved using an external ceramic membrane avoiding itaconate product inhibition. Thereby, itaconate production was increased 3-fold. The successful incorporation of CO2-derived substrate utilization within this work combined with metabolic engineering and bioprocess optimization improved Ustilaginaceae itaconate production. The here presented results contribute to the production of itaconate from sustainable carbon sources, with the overall goal of reducing land use and carbon footprints.

Given the persistent growth in demand for food, energy, and chemicals in the coming decades, a shift from fossil-based raw materials to sustainable alternatives is required. Using renewable carbon sources will allow a future that is independent of fossil carbon. Itaconate functions as a bio-based building block with many applications. This work focused on metabolic engineering and bioprocess optimization strategies to establish a sustainable Ustilaginaceae itaconate production using CO2-derived co-substrates.