Successful Construction Supply Chain Management: Concepts and Case Studies » książka

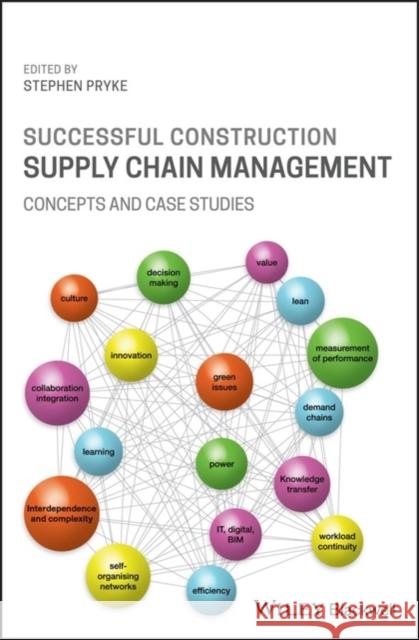

Successful Construction Supply Chain Management: Concepts and Case Studies

ISBN-13: 9781119450689 / Angielski / Twarda / 2020 / 384 str.

Successful Construction Supply Chain Management: Concepts and Case Studies

ISBN-13: 9781119450689 / Angielski / Twarda / 2020 / 384 str.

(netto: 490,79 VAT: 5%)

Najniższa cena z 30 dni: 503,91

ok. 30 dni roboczych.

Darmowa dostawa!

List of Contributors xvPreface xxiAcknowledgements xxiii1 Introduction 1Stephen Pryke1.1 Overview: Part A 21.1.1 IT, Digital, and BIM 21.1.2 Self-Organising Networks in Supply Chains 21.1.3 Green Issues 31.1.4 Demand Chains and Supply Chains 41.1.5 Lean 51.1.6 Power Structures and Systemic Risk 51.1.7 Decision-Making Maturity 61.2 Overview: Part B 71.2.1 Lessons from Megaprojects 71.2.2 Collaboration and Integration 81.2.3 Lesson Learned and Findings from Tier 1 Contractors 81.2.4 Lean Practices in The Netherlands 91.2.5 Knowledge Transfer in Supply Chains 101.2.6 The Role of Trust in Managing Supply Chains 101.3 Summary 11References 11Part I Chapters that Principally, but not Exclusively, Deal with Concepts and the Development of Theory 132 The Digital Supply Chain: Mobilising Supply Chain Management Philosophy to Reconceptualise Digital Technologies and Building Information Modelling (BIM) 15Eleni Papadonikolaki2.1 Introduction 152.2 The Nature of Construction 172.2.1 Addressing Existing Complexity and Fragmentation in Construction 172.2.2 Advancements from Other Industries Applicable to Construction 172.2.3 Potential Synergies Between Supply Chain Management and Digitisation 192.3 Origins and Development of Supply Chain Thinking in AEC 202.3.1 The Emergence of Supply Chain Thinking from Operations and Logistics Research 202.3.2 The Adaptation of Supply Chain Management Concepts in AEC 212.4 Pragmatic Impact of Supply Chain Thinking in Construction 222.4.1 Supply Chain Thinking Schools 222.4.2 Supply Chain Concepts and Varying Interpretations 232.5 Origins and Development of Digitisation in the Built Environment 232.5.1 Development of Digital Capabilities in the Built Environment 232.5.2 From Building Product Models to Building Information Modelling (BIM) 252.5.3 Importance of Standards in a Digital Built Environment 252.5.4 Pluralism of Digital Artefacts and BIM Maturity Assessment Methods 262.6 Pragmatic Impact of Digitisation and BIM 282.6.1 BIM and the Enterprise: Bottom-Up Adoption 282.6.2 BIM and the Institutional Setting: Top-Down Diffusion 282.6.3 Mismatch Between Top-Down and Bottom-Up Strategies 292.7 Synthesis of Digital Technologies Construction Supply Chain 302.7.1 Potential and Outlook of Digital Technologies to Support Supply Chains 302.7.2 Co-Evolution of Supply Chain Management and Digital in AEC 312.8 Conclusion 32References 343 At the Interface: When Social Network Analysis and Supply Chain Management Meet 43Huda Almadhoob3.1 Introduction 433.2 Reconceptualising Supply Chains 443.3 Supply Networks as Complex Adaptive Systems 453.4 What Is Social Network Analysis? 503.5 Rationale for a Network Approach 523.6 Key Challenges in Conducting Social Network Analysis 543.7 Conclusions and Directions for Future Research 553.8 Managerial Implications 56References 574 Green Supply Chain Management in Construction: A Systematic Review 63Niamh Murtagh and Sulafa Badi4.1 Introduction 634.1.1 Environmental Impact of Construction 644.1.2 Definition 654.2 Research Methodology 664.2.1 Stage 1: Define Eligibility Criteria 664.2.2 Stage 2: Define Search Terms 674.2.3 Stage 3: Search, Screen, and Compile List of Included Papers 674.2.4 Stage 4: Code and Critically Evaluate Included Studies 674.2.5 Stage 5: Formulate Synthesis 684.3 Analysis 684.3.1 Research Interest over Time 684.3.2 Source Journals 684.3.3 Geographic Spread 694.3.4 Methods 694.3.5 Tools and Techniques 724.3.6 Stakeholders 734.3.7 Definitions of Green Supply Chain Management 744.4 Discussion 754.4.1 Overview 754.4.2 Definition 754.4.3 Nature of Construction 764.4.4 Stakeholder Roles 774.4.5 Practical Recommendations 774.5 Looking to the Future 784.6 Conclusion 80References 815 Connecting the 'Demand Chain' with the 'Supply Chain': (Re)creating Organisational Routines in Life Cycle Transitions 87Simon Addyman5.1 Introduction 875.1.1 The Temporal Paradox in Temporary Organising 895.2 The Construction Industry - Procurement and Relational Difficulties 905.3 Temporary Organisations and the Project Life Cycle 925.4 Routines and the Capability of Projects 955.5 A Recursive Process Model of Transitioning 985.6 Discussion 1015.7 Summary 103References 1046 Construction Supply Chain Management through a Lean Lens 109Lauri Koskela, Ruben Vrijhoef and Rafaella Dana Broft6.1 Introduction 1096.2 Theoretical and Philosophical Grounding of Lean 1106.2.1 Theoretical and Philosophical Grounding of the Mainstream Approach to Production Management 1106.2.2 Theoretical and Philosophical Grounding of Lean 1116.2.2.1 Theory of Production 1116.2.2.2 Epistemology of the Lean Concept 1126.2.2.3 Ontology of the Lean Concept 1126.2.3 Implications for Management and Organising 1136.3 Theoretical Background and Characterisation of Supply Chain Management 1146.3.1 Production Perspective 1146.3.2 Economic Perspective 1156.3.3 Organisational Perspective 1166.3.4 Social Perspective 1166.4 Analysis of Supply Chain Approaches and Conceptualisations through a Lean Versus Mainstream Lens 1176.5 Contingency of Supply Chain Management in Construction through a Lean Lens 1186.5.1 Construction from a Production Perspective 1196.5.2 Construction from an Economic Perspective 1196.5.3 Construction from an Organisational Perspective 1196.5.4 Construction from a Social Perspective 1216.5.5 A Crossover of Supply Chain Management and Lean in the Context of Construction 1216.6 Discussion 1216.7 Conclusion 122References 1227 Supply Chain Management and Risk Set in Changing Times: Old Wine in New Bottles? 127Andrew Edkins7.1 Introduction and Overview 1277.2 The Collapse of Carillion: Consequences for Consideration - Implications for Construction Supply Chains 1297.3 Risk, Power Structures, and Supply Chains 1327.3.1 Commercial Power and the Role of Law and Regulation 1337.3.2 Technology-Based Power Structures: Cases of Construction Waste and BIM 1357.4 Conclusions 139References 1408 Linkages, Networks, and Interactions: Exploring the Context for Risk Decision Making in Construction Supply Chains 143Alex Arthur8.1 Introduction 1438.2 The Evolution of the UK Construction Industry and Supply Chain Relationships 1448.3 The Concept of Risk 1478.3.1 Uncertainty 1498.3.2 Probability 1508.3.3 Risk as a Potential Future Event 1508.3.4 The Impact of a Risk Event on an Objective or Interest 1508.4 The Construction Risk Management System 1508.4.1 Risk Identification Subsystem 1528.4.2 Risk Analysis Subsystem 1538.4.3 Risk Response Subsystem 1538.5 Risk Generation in Construction Supply Chain Relationships 1548.5.1 Project Risk Events Generated through the Project Delivery Processes 1548.5.2 Project Risk Events Generated through the Network and Interactions within Construction Supply Chain Relationships 1558.6 Risk Management Decision-Making Systems in Construction Supply Chain Relationships 1568.7 Conclusion 159References 1619 Culture in Supply Chains 167Richard Fellows and Anita Liu9.1 Introduction - Context 1679.2 Culture 1709.3 Dimensions of Culture 1739.3.1 National Culture 1749.3.2 Organisational Culture 1769.3.3 Fitting with Other Cultures 1809.3.4 Organisational Climate 1829.3.5 Project Atmosphere 1829.3.6 Behaviour Modification 1839.4 Values and Value 1839.5 Ethics 1859.6 Organisational Citizenship Behaviour (OCB) and Corporate Social Responsibility (CSR) 1879.7 Teams and Teamwork 1889.8 Sensemaking 1899.9 Motivated Reasoning 1909.10 (Strategic) Alliances 1929.11 Supply Chain Participants and Behaviour 1949.12 Conclusion 199References 201Part II Chapters that Principally, but not Exclusively, Deal with Case Study Material 21110 Managing Megaproject Supply Chains: Life After Heathrow Terminal 5 213Dr Juliano Denicol10.1 Motivation for the Research 21310.2 Construction Supply Chain Management 21410.2.1 Temporary vs Permanent Supply Chains (ETO vs MTS) 21710.3 Why Are Megaprojects So Important? 22110.4 Megaproject Supply Chain Management 22310.5 Conclusion 228References 23111 Anglian Water @one Alliance: A New Approach to Supply Chain Management 237Grant Mills, Dale Evans, and Chris Candlish11.1 Introduction 23711.2 Supply Chain Management 23811.3 Alliance Supply Chain Management 23911.4 Anglian Water Alliance Case Study 24011.4.1 Strategic Approach to Alliance Supply Chain Management 24011.4.2 Alliance Supply Chain Work Clusters 24111.4.3 Alliance Supply Chain Early Involvement and Collaboration 24211.5 Evaluation of the Value of Alliance Supply Chain Management 24411.5.1 Strategic Approach to Alliance Supply Chain Management 24411.5.2 Alliance Supply Chain Management Provides an Effective Environment for the Early Engagement of Specialist Suppliers 24411.5.3 Alliance Supply Chain Management Can Create a Win-Win-Win Reciprocal Relationship 24511.5.4 Alliance Supply Chain Management Can Drive Team Innovation and Create New Service Relationships 24511.5.5 Long-Term Approaches to Alliance Supply Chain Management Can Drive Strategic Business Benefits 24611.5.6 Alliance Supply Chain Management that Uses Advanced Production Systems Can Deliver Tactical Benefits 24611.6 Conclusions 246References 24712 Understanding Supply Chain Management from a Main Contractor's Perspective 251Emmanuel Manu and Andrew Knight12.1 Introduction 25112.2 Multilayered Subcontracting in the Construction Industry 25212.3 Supply Chain Management: Principles and Practices 25412.4 Supply Chain Management Practices from a Contractor's Perspective 25612.5 Case Study of a Large UK Main Contractor 25712.5.1 Supply Chain Management Goals 25812.5.2 Supply Chain Management Team 25912.5.3 Supply Chain Management Classification 26012.5.4 Supply Chain Management Practices 26112.5.4.1 Audit Supply Chain Firms 26112.5.4.2 Use Collaborative ICT Systems 26312.5.4.3 Measure Performance of Supply Chain Firms 26312.5.4.4 Engage in Continuous Performance Improvement Activities 26412.5.4.5 Develop Long-Term Collaborative Relationships 26412.5.4.6 Motivate and Incentivise the Supply Chain 26512.6 Conclusion 265References 26713 Lean Supply Chain Management in Construction: Implementation at the 'Lower Tiers' of the Construction Supply Chain 271Rafaella Dana Broft13.1 Supply Chain Management in a Project-Based Environment 27113.1.1 The Supply Chain Management Concept 27113.1.2 The Project Focus in Construction 27213.1.3 The Lower Tiers of the Construction Supply Chain 27313.1.4 A Main Contractor's Position and Role in the Construction Supply Chain 27413.2 The Characteristics of Construction 27513.2.1 Construction from a Production Perspective 27513.2.2 Construction: True Peculiarities?! 27713.3 Lean Supply Chain Management in Construction 27913.3.1 An Introduction to Lean 27913.3.2 The Role of Lean in Combination with Supply Chain Management 28013.3.3 Lean and Supply Chain Management in Construction 28113.4 Conclusion 283References 28314 Knowledge Transfer in Supply Chains 289Hedley Smyth and Meri Duryan14.1 Introduction 28914.1.1 The Supply Chain Issue 29014.1.2 Learning and Knowledge Transfer 29114.2 What Is Known - A Summary Review of the Literature 29214.2.1 The Supply Chain Ecosystem 29214.2.2 Supply Chain Learning and Knowledge Management 29314.2.3 Prequalification and Bidding Processes 29414.3 Methodology and Methods 29514.4 Findings 29614.5 Conclusions 301References 30215 Understanding Trust in Construction Supply Chain Relationships 307Jing Xu15.1 Introduction 30715.2 Towards an Understanding of Trust in Construction Supply Chains 30815.2.1 Towards a Service-Dominant Logic View 30815.2.2 Towards a Process-Based View 31115.3 Methodology and Methods 31415.4 Case Study 31515.4.1 Context 31615.4.1.1 Assessing the Shadow of the Past 31615.4.1.2 Organisational Structure and Policy: Forming a Sense of Unfairness 31615.4.2 Procurement and Preconstruction Stage 31815.4.2.1 Early Involvement: Forming a Sense of Security and Familiarity 31815.4.2.2 Two-stage Procurement: Creating a Sense of Equity 31815.4.2.3 The Value of Trust 31915.4.3 Execution Stage 32015.4.3.1 Structuring the Project: Maintaining Security and Familiarity 32015.4.3.2 Joint Activities: Forming the Interpretations of Trustworthiness 32015.4.3.3 Using Trust Relations in Resource Coordination: Bounded Solidarity and Economic Reciprocity 32115.4.3.4 The Value of Trust 32215.4.4 Completion Stage 32315.4.4.1 Stabilising the Relationship: Trust as a Rule of Legitimation 32315.4.4.2 The Shadow of the Future: Social Reciprocity 32315.4.4.3 The Value of Trust 32315.5 Discussion 32415.5.1 The Constitution of Trust 32415.5.2 The Value of Trust 32615.5.3 Conditions of Trust: Influences of Ecosystems and Time 32615.6 Conclusions and Recommendations 328References 32916 Summary and Conclusions 335Stephen Pryke16.1 Context -What's the Problem? 33516.2 A Summary of the Contributions 33616.2.1 IT, Digital, and BIM 33616.2.2 Self-Organising Networks in Supply Chains 33616.2.3 Green Issues 33716.2.4 Demand Chains and Supply Chains 33716.2.5 Lean 33716.2.6 Power Structures and Systemic Risk 33716.2.7 Decision-Making Maturity 33816.2.8 Culture 33816.2.9 Lessons from Megaprojects 33816.2.10 Collaboration and Integration 33916.2.11 Lesson Learned and Findings from Tier 1 Contractors 33916.2.12 Lean Practices in The Netherlands 34016.2.13 Knowledge Transfer 34016.2.14 The Role of Trust in Managing Supply Chains 34116.3 Key Themes and Agendas for Research and Practice 34116.3.1 Complexity and Interdependence 34116.3.2 Work Packages 34116.3.3 Resistance to Change 34216.3.4 Risk 34216.3.5 Communications and Integration of Systems and the Green Agenda 34316.3.6 The Role of the Contractor 34316.3.7 The Role of the Client 34316.3.8 Lean Construction 34316.3.9 Collaborative Behaviour and Quality of Relationships 34416.4 Final Remarks 344References 344Index 347

STEPHEN PRYKE, FRICS, MSc, PhD, PGCertEd, DipS, MCMI, is Professor of Supply Chain and Project Networks, and Course Director of the MSc Project and Enterprise Management at the Bartlett School of Graduate Studies, University College London. He is also Director of Postgraduate Teaching and Learning at the Bartlett School of Graduate Studies, UCL and Director of the Centre for Organisational Network Analysis (CONA@UCL). Stephen worked closely with the leading exponents of supply chain management worldwide before joining UCL full time. He previously provided project management training and consultancy to a number of major European companies and has been a consultant with Durland Consulting in Chicago. His main research interests involve supply chain management and the application of social network analysis in the study of construction project networks.

1997-2026 DolnySlask.com Agencja Internetowa

KrainaKsiazek.PL - Księgarnia Internetowa