Gearwheel Manufacturing Technology » książka

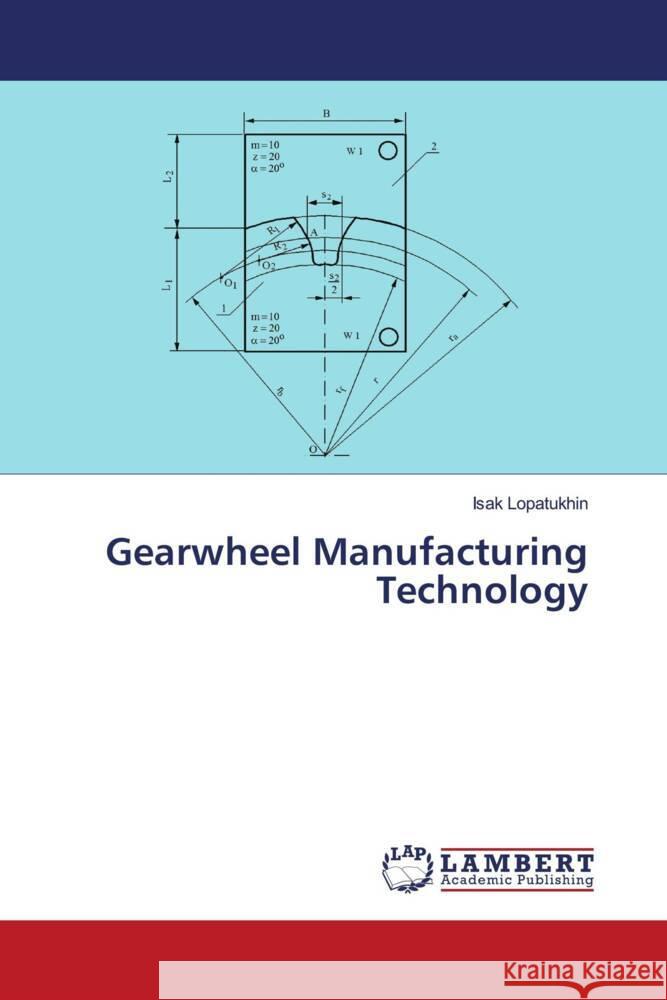

Gearwheel Manufacturing Technology

ISBN-13: 9786204728353 / Angielski / Miękka / 56 str.

Various gearwheels are used in mechanical engineering: cylindrical (cylindrical and helical), single-rim and multi-rim (block), conical with straight, oblique or circular teeth, worm wheels, internal gearing wheels, as well as gear racks, gear sectors, bevels, noncircular gears, gear shafts.Gearwheel teeth can be produced by means of copying, hobbing, or rolling.When repairing various machines or mechanisms, it is often necessary to manufacture gearwheels that are designed in different systems according to different standards and in different countries. Any given company might not have a necessary tooth-cutting tool for their machining. When making a tooth-cutting tool, i.e., a cutter or mill, the profile of the involute part can be replaced by circles whose centers lie on the base circle of the wheel. Hot and cold rolling of teeth with knurls is performed without removing shavings by means of plastic deformation.After cutting the teeth of a gearwheel,you should check tooth thickness along chord of the pitch circle at distance from the circumference of protrusions.For finishing unhardened teeth of gearwheels, the following operations are used: running-in, rolling and shaving.