Applied Thermodynamics in Unit Operations » książka

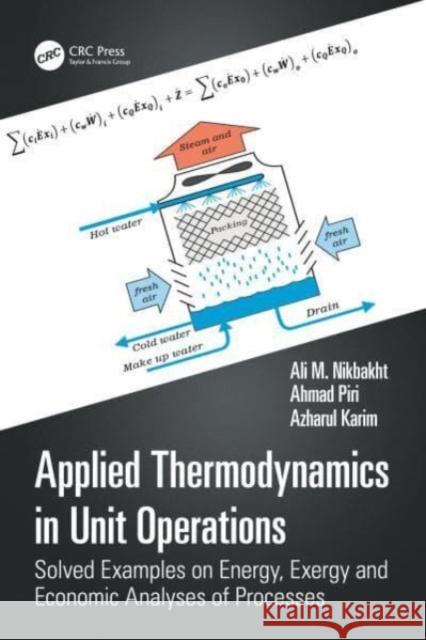

Applied Thermodynamics in Unit Operations

ISBN-13: 9781032543956 / Twarda / 2023 / 400 str.

Applied Thermodynamics in Unit Operations

ISBN-13: 9781032543956 / Twarda / 2023 / 400 str.

(netto: 673,60 VAT: 5%)

Najniższa cena z 30 dni: 604,49

ok. 16-18 dni roboczych.

Darmowa dostawa!

The growing demand of energy accounting is the main challenge for engineers working in chemical processing plants, food industries, and the energy sector. This book offers a clear contribution to the quantification of energy consumption in processes, while solving the economic aspects of energy that are vital in real-life industrial contexts.

Wydanie ilustrowane

Chapter 1. Introduction and Concepts. 1.1. A Short Review of Thermoynamics. Chapter 2. Mass Balance. 2.1. Mass Flow. 2.2. Volumetric Flow. 2.3. Mass Balance. 2.4. Material Balance. Chapter 3. Energy Balance. 3.1. Energy Balance. 3.2. Energy Balance of Closed Systems. 3.3. Thermophysical Properties. Chapter 4. Entropy. 4.1. Reversible and Irreversible Process. 4.2. Irreversibility Factors. 4.3. Internal and External Irreversibility. 4.4. Entropy. 4.5. Isentropic process. 4.6. Gibbs Equations. 4.7. Entropy Change of Liquids and Solids. 4.8. Isentropic Processes in Ideal Gases. 4.9. Mechanisms of entropy transfer. 4.10. Entropy balance. Chapter 5. Exergy. 5.1. Cycle. 5.2. Thermal engine. 5.3. Carnot Cycle. 5.4. Exergy of heat. 5.5. Exergy of work. 5.6. Exergy of mass. 5.7. Exergy of ideal gas. 5.8. Thermal and mechanical exergy of mass flow. 5.9. Cold and hot exergy. 5.10. Destruction of exergy. 5.11. Exergy balance. Chapter 6. thermodynamic analyses in unit operations. 6.1. Thermodynamic Analyses. 6.2. Energy Analysis. 6.3. Exergy Analysis. 6.4. System losses. 6.5. Application of tehrmodynamics in the food industry. 6.6. Thermophysical Properties of Agricultural Products and Food. 6.7. Energy analysis in unit operation. 6.8. Reversible work of steady flow. 6.9. Isentropic Efficiency of Steady Flow Equipment. 6.10. Case examples from the food industry. Chapter 7. Pschycrometry and Drying. 7.1. Mixture. 7.2. Gas Mixtures. 7.3. Properties of a Mixture of Ideal Gases. 7.4. Analysis of Humid Air. 7.5. Adiabatic Saturation Process. 7.6. Psychrometry Chart. 7.7. Thermodynamic Processes of Humid Air. 7.8. Cooling Tower. 7.9. Exergy of moist air. 7.10. Drying. Chapter 8. Exergy-Economic Analysis. 8.1. Concepts of exergy-economic analysis. 8.2. Heat exchanger. 8.3. Pump. 8.4. Mixing. 8.5. Evaporator. 8.6. Separator. 8.7. Throttling valve. References. Appendices

Ali M. Nikbakht is an experienced engineer in energy storage systems. He has lectured and conducted industrial engaged research programs at Urmia University and Queensland University of Technology. Having worked in internal combustion engine test rooms, he obtained extensive experience in testing energy systems along with techno-economic assessment of thermal operations. He has presented workshops and seminars in thermal engineering, steam generation and distribution, HVAC and techno-economic evaluations in real-life industrial processes under the framework of 4E (energy, exergy, economy, and environment). He has commissioned the bio-energy laboratory, where solar collector simulator, fluid dynamics experimentation, biomass conversion technologies (pyrolysis and transesterification) are practiced. As a senior consultant in launching engine test room at Urmia University, he has presented novel and innovative approaches for testing, instrumentation and validation.

Broad Areas of Research

• Energy storage systems

• Techno-economic analysis of energy systems

• Computational fluid dynamics in energy systems

• Exergy and energy in unit operations and processing industry

Ahmad Piri is a postdoctoral fellow at Urmia University, engaged in thermal evaluations of unit operations. He has a demonstrated track record of working in drying, steel, food processing, and chemical industries. Piri has been successful in monitoring the process flow of sugar processing plants and simulation evaporation and crystallization of sugar using thermodynamics and heat/mass transfer principles. He is now consulting the processing plants to develop process flow diagrams and dynamic models by Hysys and EES. Ahmad is a member of a young research team who has initiated a startup on novel drying technologies. His extensive insight on energy calculations has been demonstrated by the stakeholder when giving consultancy to thermal engineering industries.

Broad Areas of Research

• Exergy and Thermodynamics

• Thermal engineering in fruit/food processing

• Steady-state simulation of processes in Hysys

Azharul Karim is currently working as a Professor in the School of Mechanical, Medical & Process Engineering (MMPE), Queensland University of Technology (QUT) and the director of Advanced Drying and Sustainable Energy Research (ADSER) Group (https://research.qut.edu.au/adser/). His research is directed towards uncovering fundamental understanding of drying process by developing advanced multiscale and multiphase models using theoretical/computational and experimental methodologies. Through his scholarly, innovative, high quality research, he has established his national and international standing in his field. He has authored over 230 peer-reviewed articles, including 140 high quality Journal Papers, five books and 13 book chapters. His papers have attracted more than 7000 Scholar citations with h-index of 46. He is the editor/board member of six reputed journals including Drying Technology and Nature Scientific Reports. He has been keynote/distinguished speaker at scores of international conferences including International Drying Symposium (2022) and invited/keynote speaker in seminars in many reputed universities including Oxford University (2018) and the University of Illinois (2022). He has been awarded 21 research grants amounting about A$4 million and won multiple international awards for his outstanding contributions in multidisciplinary fields. He is the recipient of highly prestigious ARC Linkage (2021) and ARC Discovery grants (2022) at first chief investigator. He is also a leader in innovative application of ‘Lean Manufacturing’ concepts in hospital emergency departments to reduce long waiting times and optimize resources. Dr Karim is the inventor of many innovative new products including (1) Ultrasonic washing machine (patent WO02089652) (2) Ultrasonic dishwasher (patent WO0229148) (3) Advanced independent solar drying system (Patent 2019900943) and (4) Integrated heat pump, vacuum and microwave convective drying system (Patent 2019900942). Dr Karim’s high-level achievements in both fundamental and applied research in the important area of Advanced Drying and Microwave Heating has established him as one of the world’s leading researchers in these fields as demonstrated by his Field Weighted Citation Impacts (FWCI) of 2.24 and 9.82 respectively.

Broad Areas of Research

• Multi-scale and Physics Based Modelling in Drying

• Renewable Energies and Sustainable Processing

• Artificial Intelligence and Advanced Modelling in Agri-industrial Processes

• Nano fluid solar thermal storage

• Concentrating PV-thermal collector

• Thermal Storage

• Lean Manufacturing and Lean Healthcare System

1997-2026 DolnySlask.com Agencja Internetowa

KrainaKsiazek.PL - Księgarnia Internetowa